Imagine a manufacturing world where every process hums with efficiency, precision, and intelligence. Where machines anticipate your needs, seamlessly adapting to ever-changing demands. In this awe-inspiring landscape, data reigns supreme, guiding decision-making with unprecedented insights. The result? Production capabilities that defy imagination, unlocking new frontiers of productivity and creativity.

It may sound futuristic, but the future is here, and it’s nothing short of extraordinary; we live in an era of Industry 4.0, where science fiction meets reality, and innovation knows no bounds. Let’s get ready to witness the fusion of technology and manufacturing like never before as we embark on this transformative journey together, so what exactly is Industry 4.0? Let’s answer this question!

What Exactly is Industry 4.0?

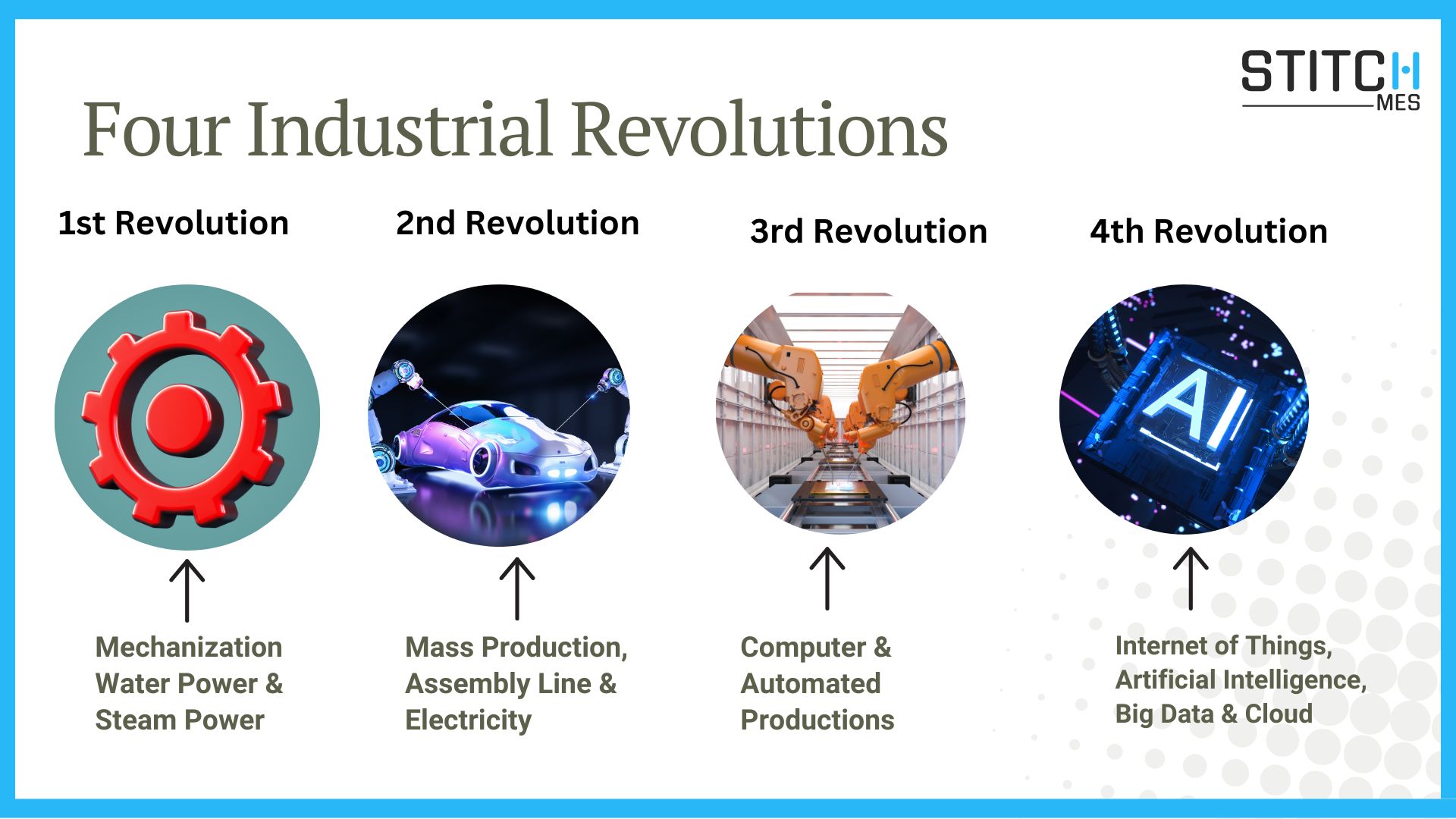

Let’s take a trip back in time where steam engines powered the original Industrial Revolution, while electricity electrified the second. The third revolution saw the birth of preliminary automation and machinery. But now, we find ourselves amid the fourth wave (not the Corona wave), where powerful computers are the driving force behind this awe-inspiring transformation. If you look closely, human-machine interactions are blurring the boundaries between reality and imagination, with virtual reality, augmented reality, robotics, automation, and autonomous guided vehicles leading the charge.

But Is There a Catch?

Technology is only one-half of the equation in Industry 4.0. Companies must ensure their workforce is equipped with the right skills through upskilling and reskilling to truly thrive in this transformation era. It’s about learning new skills to enhance current roles and embracing the challenge of reskilling workers for entirely new positions within their organizations. It’s no longer just about the physical adaptations of species but also about the adaptability and agility of companies in the face of relentless technological advancements. Adapting, pivoting, and reinventing oneself is the key to survival. Like in nature, where species must adapt to changing environments, businesses must navigate the turbulent seas of technological disruption and emerge stronger and more resilient.

Surviving in this Digital Age with Darwin’s Theory

So, as we embark on this remarkable journey through Industry 4.0, let us remember the lessons from nature’s playbook. It is not the strongest that survive, nor the most intelligent. It is those who are willing to embrace change, evolve and transform who will flourish in this digital landscape. Embrace the spirit of “Survival of the fittest” in Industry 4.0. Adapt, innovate, and let the winds of change carry you towards a future filled with endless possibilities. Together, we will navigate the challenges, seize the opportunities, and build a resilient and thriving tomorrow.

Electrifying Impact: The Industrial Revolution Revolutionizes the Apparel Industry

Industrial Revolution 4.0 is poised to impact every industry, but in this blog, we are going to talk about its impact on the apparel industry explicitly; the truth is many organizations have jumped on the ‘Industry 4.0’ bandwagon, but Shahi Exports, India’s largest apparel manufacturer has gone beyond mere lip service and taken concrete steps to embrace the importance of this revolutionary wave. In 2019, they joined hands with NIFT (national institute of fashion technology) & demonstrated that they are ready to disrupt the apparel manufacturing industry. The apparel manufacturing company and various companies are paving the way for Industry 4.0 in the industry.

Enter Cognex, an American manufacturer of machine vision systems, sensors, and software that can swiftly detect flaws and deviations, eliminating laborious manual inspections. With Cognex’s game-changing solution, manufacturers can enhance production efficiency, reduce defects, and increase speed, all while slashing costs.

The second name is Datacolor, a leading provider of color management tools paving the way for advanced color management with its range of AI instruments and software that leverages sensors to achieve precise color matching within predefined tolerance limits.

The third name is Stitch MES, a complete apparel software suite that seamlessly integrates with every apparel business. It simplifies reporting, manages warehouses and offers a full power dashboard where every minute operations can be tracked. It is designed to propel the apparel industry towards 4.0 and move towards smart manufacturing by digitizing production shop floor operations with minimum investments.

Conclusion

The biggest question is, are we ready to join the ranks of innovators and pioneers ushering in the Fourth Industrial Revolution? Let’s dive headlong into this exciting era of transformation, where human potential meets cutting-edge technology, and together, we’ll unlock a future.

Leave A Comment