HOW IT WORKS

Strategically plan the equipment usage and increase the asset lifespan and utilization.

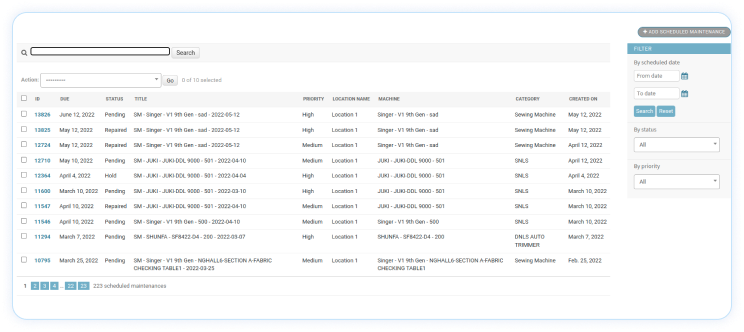

Maintenance Planning & Scheduling

Proactive maintenance planning and scheduling is at the heart of improving machine’s up time and life. Maintenance calendar visibility for the mechanics.

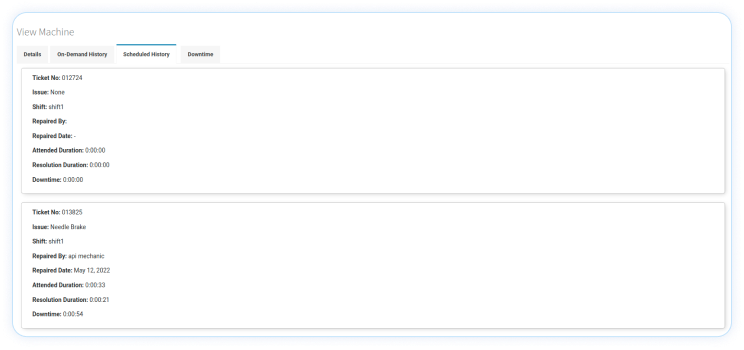

Maintain Safety & Compliance Regulations

Detailed documentation of work history and machine usage with standardized inspection & checklists to reduce risk & liability.

Maintain safety & compliance regulations

Detailed documentation of work history and machine usage with standardized inspection & checklists to reduce risk & liability.

Minimize Downtime

Increase asset performance and resolve issues quickly through effective & reliable management of equipment maintenance & servicing schedule.

FEATURES

Easily monitor & manage your assets and optimise the workforce operations at your factory.

Inventory Management

Monitor tool parts and machines to track the inventory usage and stock availability. Get detailed tool consumption history to make better decisions regarding maintenance and machine handling.

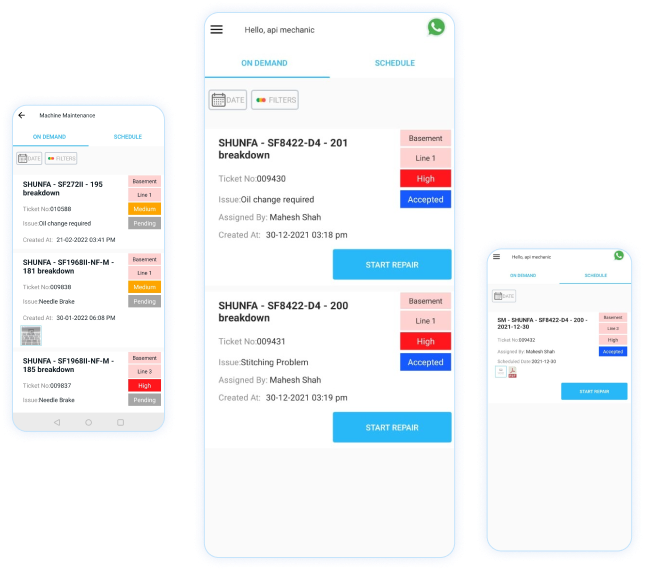

Breakdown Maintenance

Save yourself last minute delays by assigning orders automatically to best personnel for certain events to bring the machines up quickly when critical productions are at stake.

Downtime Tracking

Trace and record the total downtime and uptime of the machines and tools and use this summarized data to make informed decisions.

Actionable Intelligence

Speed up responses to breakdown by connecting maintenance staff and empowering them to manage malfunctions and repair work.

Preventive Maintenance

Generate preventive maintenance work orders automatically whenever the maintenance is due and distribute work orders to maintenance staff. Plan maintenance work & manage maintenance procedures

Predictive Maintenance

Maintenance tasks can be automatically triggered through the system when specified maintenance conditions arise.