The fashion industry, once synonymous with creativity and self-expression, has also earned a reputation for being one of the largest contributors to environmental waste and pollution. The apparel manufacturing sector—with its vast, intricate supply chain—produces massive quantities of textile waste and greenhouse gas emissions annually. As sustainable fashion becomes a global priority, consumers, governments, and stakeholders are demanding eco-conscious practices from brands.

This shift is largely driven by digitalization. Through the use of technology, manufacturers can revolutionize how they design, produce, and manage their products with an eye toward sustainability. It’s high time that we pioneer this movement with advanced solutions and commitment that tackles waste through recycling in the apparel industry.

The Growing Importance of Sustainability in the Fashion Industry

Sustainable practices in fashion have evolved from mere buzzwords to essential values in today’s market. In the past, sustainable methods of tackling issues in the fashion world were approached questionably as they often seemed unattainable, while the words themselves just seemed to be rhetoric. The overconsumption of this industry comes through unstable methods that invokes catastrophe to people especially those in the places that are the final destination of this wastage and pollution.

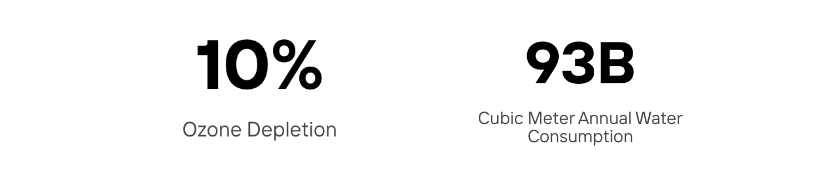

Fashion industry footprint:

Consumer awareness is also shaping the industry, with millennials and Gen Z prioritizing sustainable brands that align with their values. This shift is pushing brands to invest in sustainable fashion technology that reduces waste, optimizes resources, and promotes ethical production. Moving towards a circular economy with eco-friendly innovations has become essential for establishing a truly resilient and sustainable fashion industry.

The Role of Digitalization in Revolutionizing Eco-Friendly Manufacturing

Digitalization in manufacturing has been a game-changer, offering the fashion industry with a chance to minimize its ecological footprint while increasing productivity. Below we discuss how technology and digital changes are benefiting the sustainable efforts made in the clothing industry:

- Audits & Quality Control:

With digital tools, brands can enhance quality control measures throughout their production processes. Audits can now be conducted in real-time, ensuring that all components and materials meet rigorous sustainability and safety standards. This approach reduces waste and ensures that brands remain accountable to eco-friendly practices. - Real-Time Visibility:

The integration of real-time visibility tools allows companies to track their materials and products at each stage of the production process. This level of transparency helps detect inefficiencies early, reduces delays, and ensures sustainable practices are upheld across the supply chain. By leveraging real-time data, companies can identify areas for improvement and maintain a clear record of their sustainability progress. - Data-Driven Decision-Making:

Thanks to instant data availability, brands are now able to evaluate eco-friendliness from a sustainability perspective. Brands can examine metrics pertaining to waste generation, energy consumption and resource utilization and determine where improvement is needed. This data-centric approach promotes efficiency and helps companies minimize their ecological footprint while saving on operational costs. - On-Demand and Custom Manufacturing:

The fashion sector is being revolutionized by on-demand manufacturing and digital technologies that assist in cutting down on inventory burn. Rather than overstocking, companies now manufacture based on actual demand, determining the needed amount in real-time; this is a critical step toward better production processes and the reduction of excess production and waste.

Key Industry Trends: Technology Driving Sustainable Fashion

The intertwining of sustainability and technology in fashion industry has given rise to several promising trends, many of which are focused on circular fashion and sustainable material development. Circular fashion, or the principle of reuse, recycling, and resource recovery, is already proving to be one of the mainstream trends in the sustainable apparel industry. The development of technology has branched out trends in circular manufacturing which enable brands to easily track and reclaim materials which are integral in waste reduction.

The intertwining has given rise to new age of manufacturing practices many of which are focused on circular fashion and integrating MES solution. Like MES gives control over the flow of the production and quality controls and sustainability system brings in environment conscious to the realm of apparel manufacturing

Stitch and Cirqlar: Leading the Future of Sustainable Fashion Technology

As a pioneer in sustainable fashion technology, is way ahead in changing the conventional fashion manufacturing industry with its disruptive solutions. At Stitch, we enable apparel manufacturers to optimize their processes, manage their carbon outputs, and comply with sustainability standards without loss of quality or efficiency. Our aim is to drive sustainable growth in fashion by making sense in responsible, growth-oriented measures.

Adding to the extent of STITCH we have built Cirqlar, an advanced platform developed to aid in the recycling and reuse of by-product fabrics. CirQlar addresses a critical issue in the industry by enabling manufacturers to use Production waste as a resource and recycle, turning what would otherwise be discarded into valuable resources for new products. This not only reduces the material that ends up in the landfills but supports the notion of the circular fashion supply chain.

STITCH and Cirqlar are distinct yet complementary solutions, each playing a pivotal role in reshaping the fashion industry towards sustainability. Stitch enables on-the-go production, offering flexibility and responsiveness, while Cirqlar ensures that sustainability standards are met without compromising on quality or efficiency. These two products work in tandem to support a seamless, eco-friendly production process, each enhancing the other.

Conclusion

The sustainable shift in the fashion sector fully depends on the combination of technology with responsible sustainable practices. The industry faces the prospect where ‘digitalisation’ and ‘sustainability’ become mutually inclusive through tools like STITCH & Cirqlar. As fashion brands starts embracing the art of digital transformation in the manufacturing, they gain the insights and tools needed to drive resource efficiency, transparency, and ethical practices.

The system disruption for the fashion industry through automation and artificial intelligence solutions has only commenced, and industry players have only begun the journey of transforming the world towards sustainable technology. With the blend of investment in the right technology and commitment can ensure that the fashion industry doesn’t remain a deviant but rather a proactive sustainable practitioner. Sustainable technology solutions from providers like STITCH give an opportunity for overhauling the manufacturing processes and reducing waste in production cycles, which not only is envisaged as the future of the industry but what the world needs as well.