Tracking is a vital tool for garment manufacturers to enhance their performance in various aspects, such as efficiency, productivity, costs, quality control, transparency, and traceability. There are different methods of tracking, such as labels, barcodes, QR codes, or RFID tags. Data recording is also crucial in the garment industry, as it provides valuable data insights that help management and the team make informed decisions by identifying the gaps in the entire supply chain. Fabric tracking is one of the most important types of tracking, as fabric accounts for around 75% of the total cost in the apparel industry.

Why is traceability important in the apparel industry?

By tracing our products during production, we can analyze them in real time and reduce waste. Some of the benefits are:

- By tracing the origin and journey of their products, supply chains can find and fix inefficiencies, manage waste better, and avoid financial and reputation losses.

- Traceability ensures credibility and compliance, it enables fashion actors to adopt a circular economy model, where they can make informed choices and collaborate with trustworthy companies

- Traceability can improve product quality and value by giving more information and transparency to consumers.

Conventional Tracking Solutions

This system allows us to track the whole life-cycle of the system in every department and gather a large database for better analysis. The system is strong, but it depends on the factory’s SOPs and standards to verify the units produced in each section. However, this system had some limitations as it did not allow us to actually validate whether the garment/unit/piece has been checked or passed through that particular check point. As there has been no identification on each unit, backtracking it to the fabric also becomes difficult.

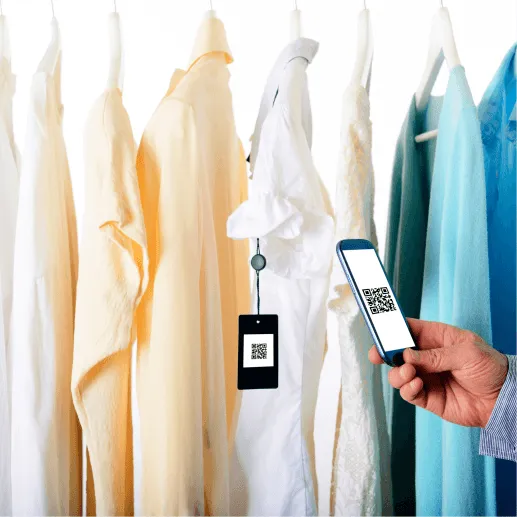

Bundle/Single Piece Tracking Via QRs

Stitch MES has revolutionized garment tracking with its single/bundle piece tracking via QR codes. This innovative feature ensures that every unit/piece/garment has passed through each section successfully. Tracking each unit also lets us trace its journey from packaging to the lay plan to the roll used for cutting. The process involves QR coding every panel/bundle along with the data related to the fabrics used. Then the bundles/single units are moved through different departments and have to be scanned at the checkpoints. These checkpoints create and prevent data manipulation, providing a strong validation.

The new system enables the manufacturers to see each QR code and trace it back to the fabric rolls used for cutting. And there’s more! The new system also has many other benefits for the manufacturers, which we will discuss next:

- Improved Efficiency and Productivity- Tracking can help garment manufacturers to identify bottlenecks and inefficiencies in their production process. This information can then be used to make improvements, such as adjusting machine speeds, rebalancing workloads, and streamlining processes.

- Reduced Costs- Tracking can help garment manufacturers to reduce costs in a number of ways. For example, by tracking inventory levels, manufacturers can avoid overstocking and understocking. By tracking production times, manufacturers can identify areas where waste can be reduced. And by tracking product quality, manufacturers can reduce the number of defective products that are produced.

- Enhanced Quality Control- Tracking can help garment manufacturers to improve the quality of their products by identifying and addressing problems early on in the production process. For example, if a manufacturer is tracking the number of defects in a particular batch of garments, they can investigate the root cause of the problem and take corrective action.

- Increased Transparency and Traceability- Tracking can help garment manufacturers to increase transparency and traceability in their supply chains. This can be important for both consumers and businesses. Consumers want to know where their clothes come from and how they are made. Businesses want to be able to track their vendor ls whether the quality raw materials has been provided throughout the journey or not.

Stitch MES has solved most of the challenges that the garment industry faces in terms of tracking each garment and increasing overall profitability. Whether it is single piece tracking or bundle tracking, Stitch MES can provide precise and real-time data on the status, location, and quality of each garment. This can help to minimize wastage, boost productivity, improve quality, and satisfy customers. Stitch MES is not just a tracking system, but a comprehensive solution for managing and optimizing the garment production process.