Are you tired of the constant struggle with production planning? Do spreadsheets, outdated systems, and unpredictable demand keep you up at night? You’re not alone. Many manufacturers grapple with these challenges daily. But what if there was a way to transform your production planning process from reactive to proactive?

The Crippling Pain Points of Traditional Production Planning

Traditional methods for managing production are often riddled with inefficiencies and prone to errors. Here are some common pain points:

- Demand Volatility: Fluctuating customer orders and unpredictable market trends make accurate forecasting a nightmare.

- Lack of Real-Time Visibility: Without real-time insights into your production floor, you’re flying blind, unable to make timely adjustments.

- Manual, Error-Prone Processes: Relying on spreadsheets and manual data entry is time-consuming and significantly increases the risk of costly errors.

- Inaccurate Data & Poor Decisions: Making critical decisions based on outdated or inaccurate data leads to inefficiencies and missed opportunities.

- Poor Communication: Siloed information flow between departments creates delays and bottlenecks.

The challenges outlined above often result in missed deadlines, escalating costs, unhappy customers, and a damaging impact on your bottom line. But there’s a smarter way forward.

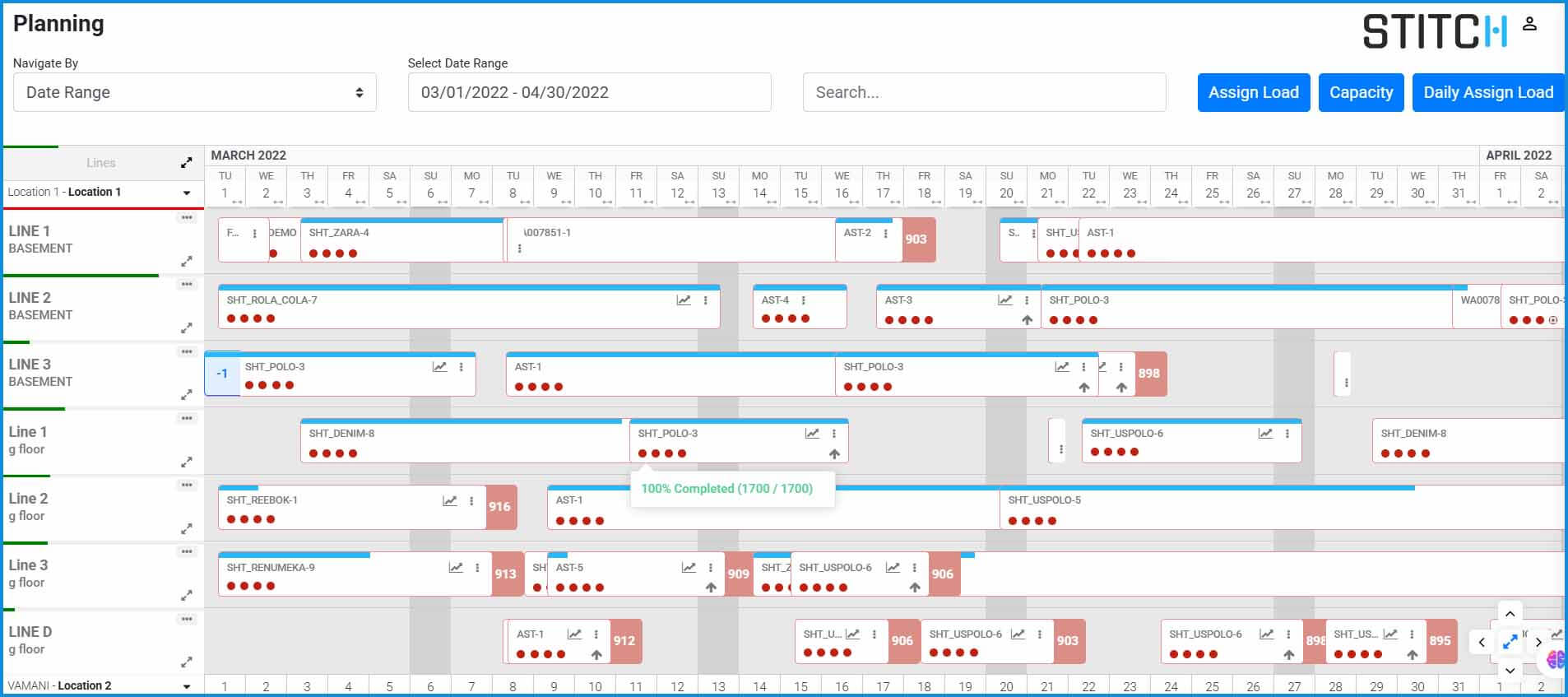

STITCH MES: Your Intelligent Production Planning & Scheduling Solution

STITCH MES is a state-of-the-art Manufacturing Execution System (MES) that redefines how you plan, execute, and optimize production. By leveraging its advanced capabilities, you can shift from reactive problem-solving to a more strategic, proactive approach—improving efficiency, reducing costs, and strengthening customer satisfaction.

Customized Production Plans: Precision Tailored to Every Order

Forget one-size-fits-all solutions. STITCH MES allows you to create highly customized production plans that align perfectly with each unique order. The intuitive “Add Production Plan” interface enables you to capture all essential details, ensuring nothing is overlooked:

- Client, Style, Order ID, and PO Number: Maintain meticulous tracking for improved order accuracy, even for the most demanding retailers.

- Factory, Season, and Profit Center: Ensure alignment with retailer preferences, compliance requirements, and internal accountability.

- Production Vendor: Streamline vendor management, particularly for retailer-preferred suppliers, fostering stronger relationships.

- Quantity, Priority, Order Start & End Dates: Meet critical deadlines and fulfil retailer demands consistently.

- Sizes and Colors: Cater to specific market needs and accurately reflect retailer demographics in your production.

STITCH MES empowers you to effortlessly adapt your production plan to changing needs. Adjust order details, shift production locations, modify schedules, and tweak quantities in real-time, ensuring your production process stays optimized.

The STITCH MES Advantage: Tangible Benefits for Your Business

Implementing STITCH MES is more than just adopting new software; it’s about transforming your entire production process and unlocking significant benefits:

- Intelligent, Adaptive Planning and Scheduling: STITCH MES automatically learns your factory’s capacity, including machine capabilities and labor skills, to create realistic production plans. It simplifies scheduling with single-click Time and Action calendars and optimizes line assignments based on real-time workloads.

- Real-Time Visibility and Proactive Issue Resolution: Gain complete, real-time visibility into order progress across all stages – pre-production, production, and post-production. Receive instant alerts about any potential delays or disruptions, allowing you to address them proactively and keep production on schedule.

- Optimized Workflow and Task Management: STITCH MES streamlines your workflow by enabling order splitting, breaking down large orders into manageable tasks. It prioritizes critical tasks through critical path management and ensures tasks are completed in the correct sequence by taking into account task dependencies, preventing bottlenecks and minimizing delays.

The Future of Manufacturing: Embrace Smart Production Planning

STITCH MES is not just a tool; it’s a strategic partner that empowers you to take control of your production planning process, optimize your operations, and achieve sustainable growth. Stop relying on guesswork and outdated methods. Embrace the future of manufacturing with STITCH MES.

Ready to Optimize Your Production?

Don’t let inefficient production planning hold your business back. Book a demo of STITCH MES today and discover how it can revolutionize your operations, boost efficiency, and drive profitability!