Cut-to-Pack Faster with Our Garments Manufacturing Software

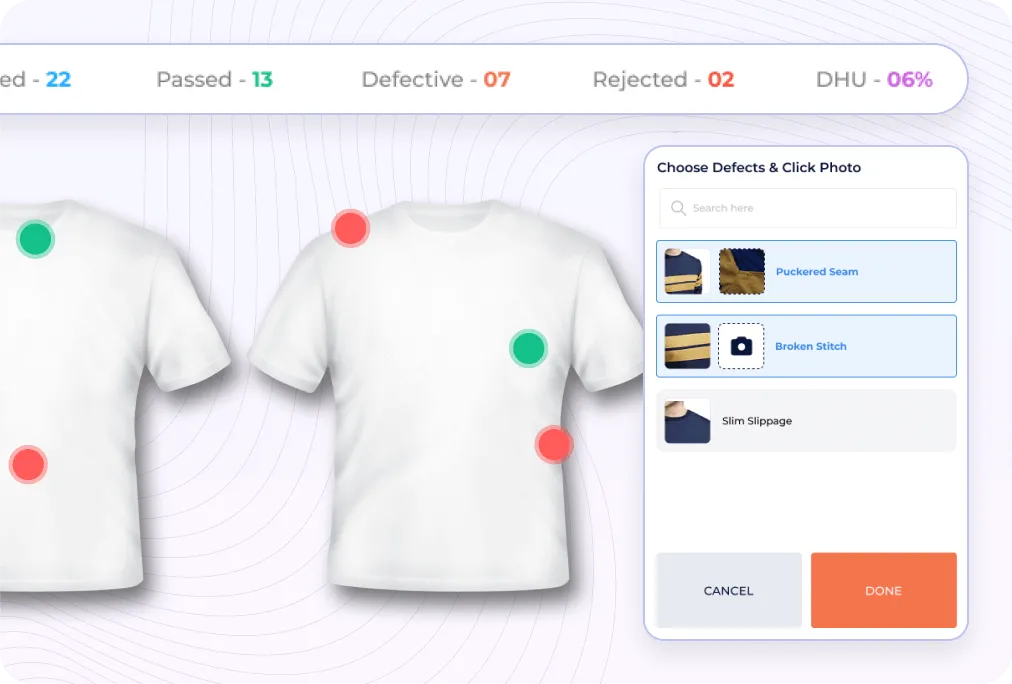

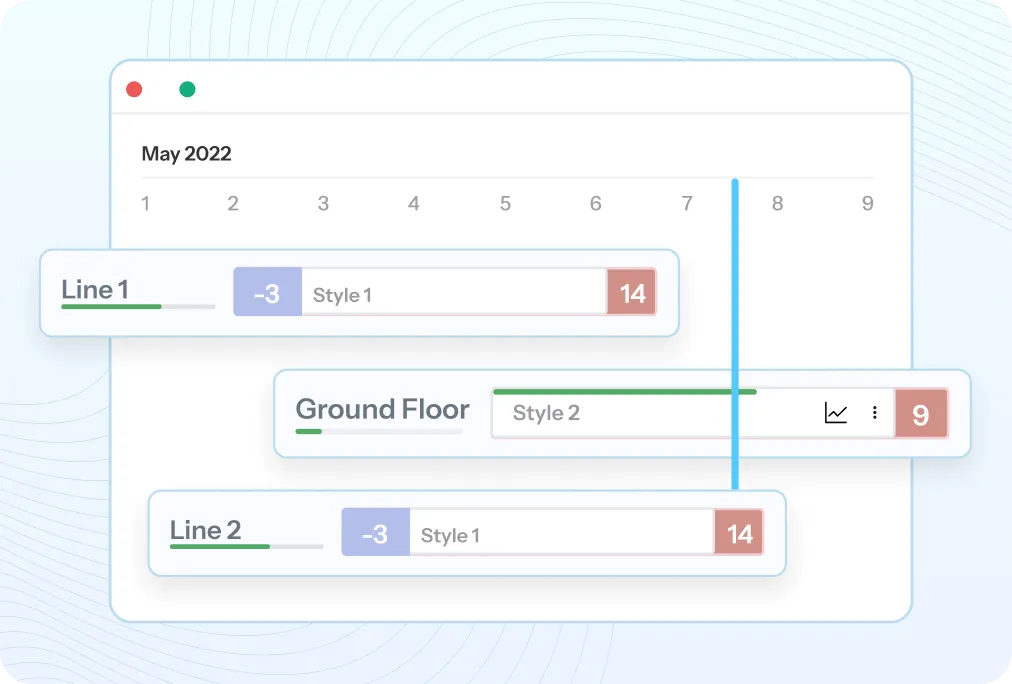

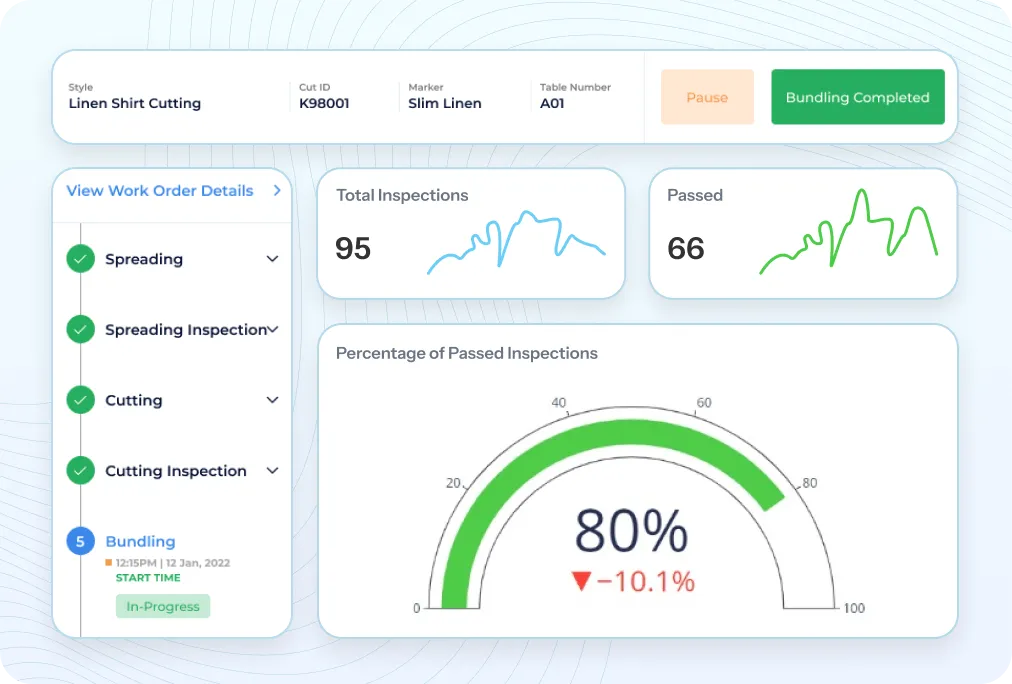

Manage quality control, track production in real-time, and control your warehouse with our all-in-one Apparel Manufacturing Software.

Fashion Manufacturers & Brands

Manage quality control, track production in real-time, and control your warehouse with one platform—the complete Software for Garment Manufacturing and Textile Manufacturing Software.

Industry Leading Expertise

Create an integrated factory

Data at Your Fingertips

Get real-time insights from every corner of your factory with manufacturing MES software. Make informed decisions, optimize production, and predict future trends – all with the power of data at your fingertips.

Collaborate with Everyone

Break down communication barriers. STITCH seamlessly connects your entire team, ensuring everyone is on the same page.

Integrate with Everything

Integrate your existing systems, machinery, and software for a smooth and unified workflow. STITCH acts as a central hub, eliminating data silos and streamlining workflows.

Sustainable Digitization

Go green, save money, and optimise for the future. STITCH Empowers sustainable practices, minimizes waste, and provides complete data on your factory’s environmental impact.

Industries we cater to

Garments

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Furniture

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Home Furnishing

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Leather Goods

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Footwear

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Hard Goods

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Garments

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Furniture

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Home Furnishing

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Leather Goods

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Footwear

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Hard Goods

Keep up with demand. Track each piece from cutting to final assembly, ensuring on-time deliveries.

Brands love working with us

A. Akilan

GM Penguin Apparel

What makes STITCH so compelling is its simplicity and ease of use. The back-end support team has been very patient in hearing our concerns and is available to help us anytime. Ever since implementing STITCH, we have had accountability for each and every piece and have had no issues tallying the production to the cut quantity. Our customer Decathlon applauded us for having such a system in the sewing line.

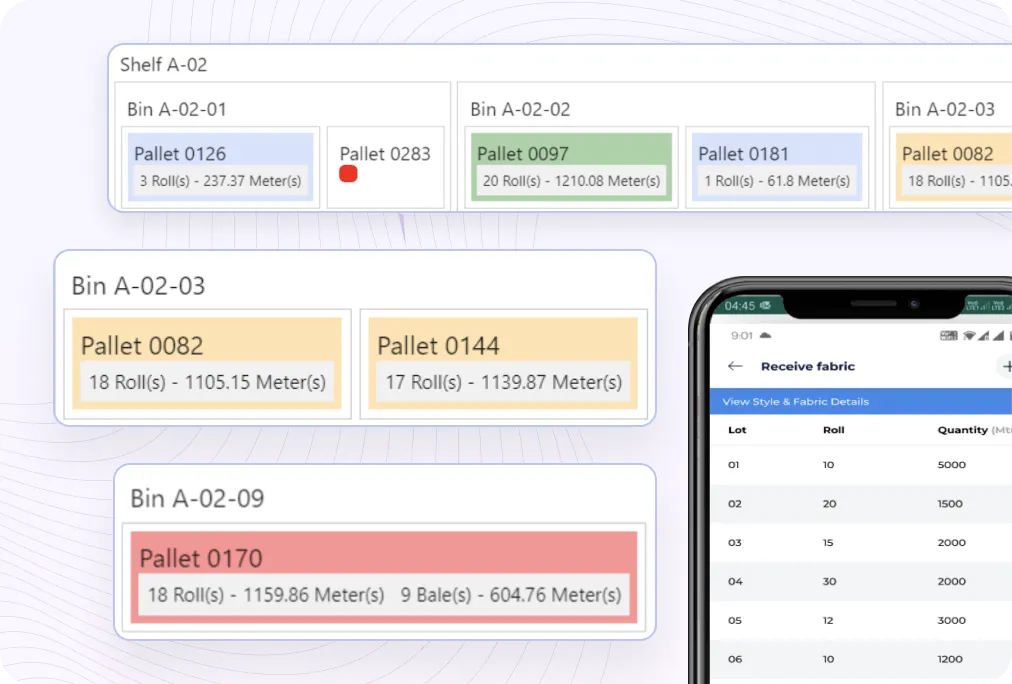

With Stitch, FutureFab can now easily manage fabric yardages, track colors and quantities, and present accurate inventory to clients. This efficiency has greatly enhanced our operations.

Tanishqa

Manager Operations FutureFab

Martin Mellblom

Partner at Scandinavian Textile & Apparel Co

We have been working with STITCH for more than six months now, and it is truly a game-changer for us. Our goals are a lot easier to reach with the data STITCH provides. The level of service we have received from STITCH (in a pandemic period) is second to none!

We find out problems within minutes rather than hours or days, and we can take action to keep our quality level.

Any apparel company that is striving to do better should use this platform. The only thing I regret is that I did not find out about STITCH many years ago.

We are using STITCH manufacturing suite software to develop advanced digital manufacturing best practices from cut to ship while reducing.

Raghav Modi

Sr. Vice President

Prakash V

CMV Global

Stitch has been a game-changer for CMV Global. Their innovative solution enabled us to achieve our sustainability goals while streamlining our operations. With real-time data, predictive analytics, and automation, Stitch empowered us to significantly reduce waste and energy consumption. Their partnership has been instrumental in our success story.

Waseem-Siddiqui

Co-Founder – FutureFab

Stitch Software has made our lives easy and helped us track our inventory in a better way. Rather than doing things manually, now everything is digitised. It is easy to manage our warehouse by putting every aspect together in a better way. We want to thank Stitch team and Durga Das for creating an amazing, workable solution, we are very happy and satisfied.

COMMON QUERIES

Frequently Asked Questions

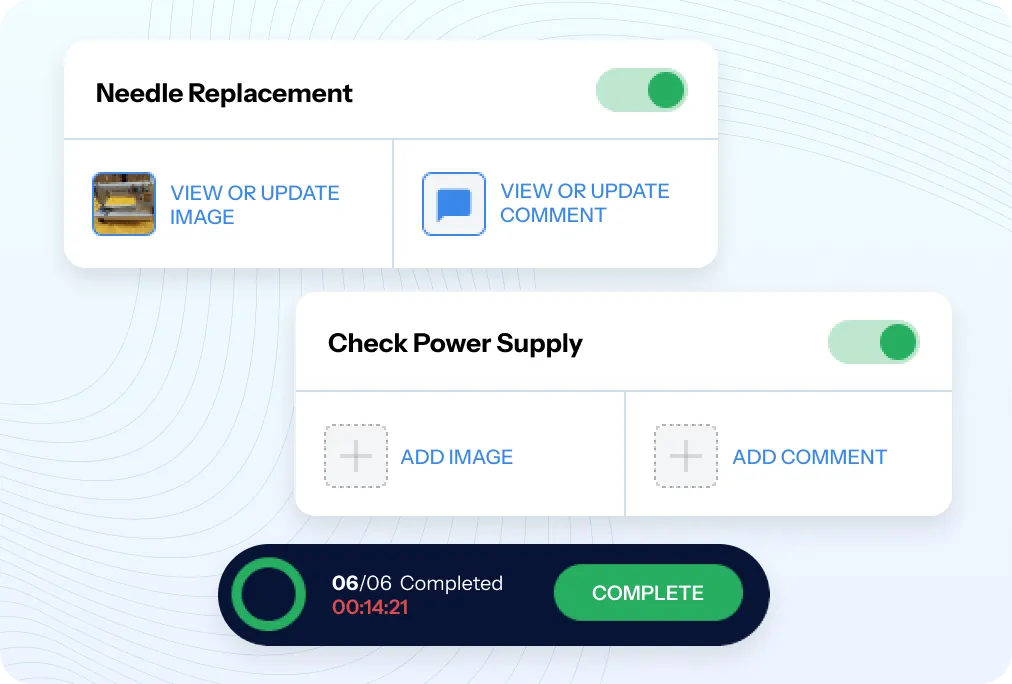

The basic ideology behind introducing the STITCH was to provide end to end solutions in a garment industry. Be it creating T&A, line planning, fabric tracking, optimized cutting plan, data tracking, quality monitoring, production tracking, streaming maintenance system, packaging, and various other shop floor solutions. STITCH got it all covered for you from order to shipment.

The implementation is quite quick! We will be up and running within 7 days. The number of days varies per the factory size, and the complete implementation will take around 30-45 days

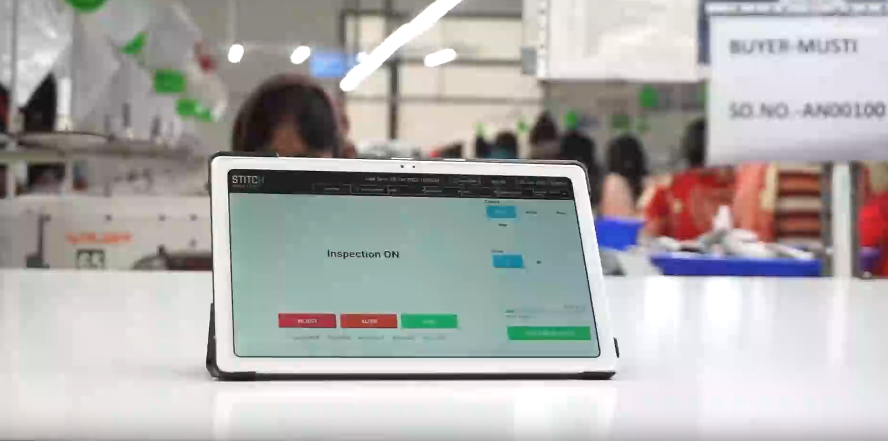

The process of starting implementing STITCH is a cake walk. Our team would visit the factory for process mapping and would provide the best and efficient method of implementing the system. The only requirement is network connectivity and basic mobile and tablet devices.

MESs and ERPs are often confused with each other but the upper hand with the MES system is real time data monitoring. In a MES system information is collected right from the operation to keep a real time track whereas in ERP we require separate operators for data feeding.

The other benefit of MES is having an enforced process, steps are in place to make sure every product is built to spec.

It provides end-to-end solutions in the garment industry. You can implement Production Planning, Time and Action, Fabric and Cutting, Quality Management, Industrial Engineering, Production Tracking, Machine Maintenance, Warehouse Management, Packaging and other shop floor solutions.

STITCH MES includes robust security features to protect sensitive data and ensure data privacy. It includes secure user authentication and access controls, encrypted data transmission and cloud storage, and our team is always ready to patch potential vulnerabilities.